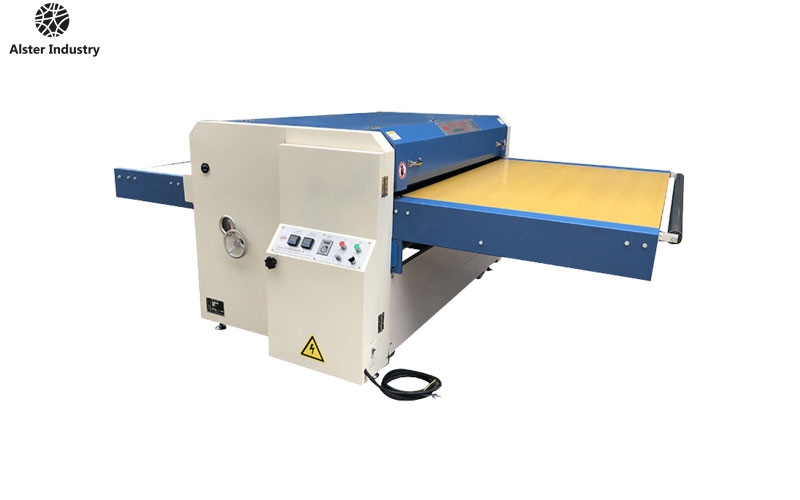

The AT-F1200 Continuous Fusing Press Machine is a high-performance, industrial-grade solution designed to meet the high-speed and high-precision demands of modern garment production. With its large fusing width, intelligent control system, and powerful heating capabilities, this machine is ideal for manufacturers producing large quantities of apparel such as suits, shirts, uniforms, and sportswear that require durable and seamless bonding of interlinings and fabrics.

Product Description

- Continuous fusing system increases the productivity.

- Equipped with the wheels for convenient mobility.

- PCB and micro switch control the upper and lower belts automatically and extends duration of the belt.

- Pressure rollers are made by silicone.which ensure the power of pressure giving is stable and equal.

- Electronic temperature constant temperature control system

- There are 6 heaters to distribute the heat evenly and can be used to all fabrics.

Application Scope

The AT-F1200 fusing machine is suitable for a wide range of garment applications, including:

- Suit and jacket production

- POLO shirts and dress shirts

- Seamless sportswear and outdoor apparel

- Uniform and industrial garment manufacturing

- High-stretch or technical textile processing

- Heat-bonding of various interlining types

Its precision and adaptability make it the perfect choice for fashion brands, contract manufacturers, and OEM garment producers.

Why Choose the AT-F1200 Continuous Fusing Press Machine?

- Exceptional Productivity: The continuous fusing system dramatically reduces downtime and improves processing efficiency.

- Precise and Consistent Results: Electronic temperature control and six evenly-distributed heaters ensure stable bonding performance across different fabric types.

- Durable Components: The use of silicone pressure rollers and automatic belt tracking enhances the machine’s longevity and ensures smooth, maintenance-friendly operation.

- Flexible Application: With a wide bonding temperature and pressure range, it adapts to virtually all types of fabrics and interlinings.

- Energy Efficient: Despite its power and size, the system is optimized to use energy wisely, helping to reduce operational costs.

- Operator-Friendly Design: From mobility to intuitive controls, the AT-F1200 is designed with the user in mind, making it easy to operate even in high-pressure production environments.

The AT-F1200 Continuous Fusing Press Machine offers an unbeatable combination of strength, precision, and smart functionality—perfect for forward-thinking manufacturers looking to scale their production capacity while maintaining top-tier garment quality.

Contact Us

Ready to take your garment production to the next level?

Invest in the AT-F1200 Continuous Fusing Press Machine and experience a new standard in fusing efficiency and precision.

👉 Contact us today for pricing, customization options, or a free consultation with our technical team.

📞 Let us help you streamline your production and boost your output with confidence!